The CCDC and Durham University Awarded Innovate UK Grant to Advance Sustainable Medicines Manufacturing through Digital Particle Engineering

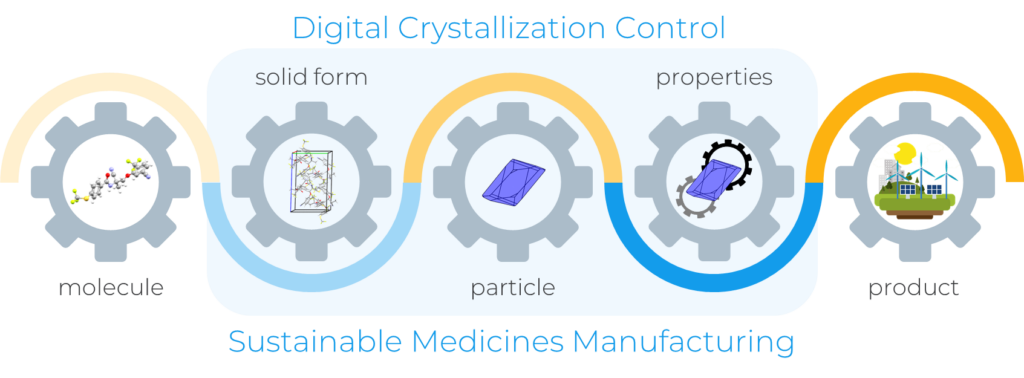

The CCDC and Durham University are proud to announce the award of an Innovate UK grant under the “Sustainable Medicines Manufacturing: Collaborative R&D” initiative. The funding will enable the integration of the ADDICT prototype software into the CCDC’s CSD-Particle suite within their established Mercury platform, advancing the digitalization of pharmaceutical manufacturing and supporting the industry’s transition to more sustainable practices.

“The integration of ADDICT into the CSD-Particle suite marks a new era of digitalization in particle engineering, empowering scientists to optimize crystallization processes with greater precision, reduced costs, and enhanced sustainability,” said Aurora Cruz Cabeza, Professor in Materials Chemistry, Durham University.

Particle engineering is a critical aspect of delivering new medicines to patients. The ability to control the shape and properties of crystalline particles is essential for efficient drug substance and product manufacturing. Poorly controlled particle attributes, such as needle-like shapes, can lead to challenges including low bulk density, susceptibility to breakage, and difficulties in particle size control. These factors increase risks and costs during drug development.

Crucial for the pharmaceutical industry’s ongoing pivot toward lower environmental impact processes, such as Continuous Direct Compression (CDC), is precise control over material properties. The trial-and-error experimental methods used for crystallization process design are resource-intensive and inefficient, underscoring the need for innovative, predictive tools to streamline development.

ADDICT (Advanced Digital Design of Industrial Crystallization Technology), developed at the University of California Santa Barbara by Professor Mike Doherty’s research group, is an academic prototype that addresses these challenges. By enabling the simulation of spiral growth crystallization under varying conditions (such as supersaturation, temperature, and solvent choice), ADDICT provides valuable insights into crystallization outcomes. However, the software is not yet ready for widespread industrial deployment.

“The crystal scientists and engineers at the CCDC and Durham University are among the best in the world, and Mercury is the gold standard for 3D crystal structure visualization and exploration. I am thrilled to collaborate with them on this new Innovate UK grant, which will deliver a new dimension to their digital design tools for crystal systems,” Mike Doherty, Mellichamp Chair in Process Systems Engineering, University of California Santa Barbara.

The Innovate UK-funded project will transform ADDICT from a promising academic prototype into a practical tool for the pharmaceutical industry. By incorporating ADDICT into the CSD-Particle suite within CCDC’s Mercury platform, the software will enable non-specialist scientists to predict and design robust crystallization processes with unprecedented efficiency. This digitalized approach will reduce reliance on experimental trial-and-error methods, cutting development times and resource consumption.

Key Benefits of the Project

- Enhanced Process Design: Integration of ADDICT will enable pharmaceutical scientists to digitally predict the impact of crystallization conditions, streamlining process design and improving outcomes.

- Sustainability Impact: By minimizing energy, raw material, and solvent use, the tool aligns with the industry’s commitment to sustainability and environmental responsibility.

- Support for Continuous Manufacturing: Facilitating CDC adoption by ensuring robust particle engineering, reducing dependency on traditional high-burden manufacturing processes.

- Increased Accessibility: Incorporating ADDICT into the Mercury platform will make advanced crystallization insights accessible to non-specialist users.

“We are thrilled to receive this Innovate UK grant, which will allow us to leverage the work done at the University of California Santa Barbara and bring it into the industrial domain,” said Andy Maloney, Particle Science Lead at The CCDC. “This project reflects our commitment to innovation, sustainability, and supporting the pharmaceutical industry in delivering life-changing medicines to patients more efficiently and responsibly.”